Designing the perfect packaging and shipping solution for your product is an art. You want something substantial and beautiful and abiding by all necessary regulations – which is where dielines come into play! An essential part of this creative process, they help you take it from concept to completion.

This blog will examine “what is a Dieline” and how to create it, its purpose, and its elements.

- What is Dieline?

- What is a Dieline in Packaging?

- What is a Dieline in Printing?

- What is a Dieline Template?

- What is a Dieline in Illustrator?

- What is a Label Dieline?

- What is the Purpose of A Dieline?

- How to Create a Dieline?

- How Do You Use a Dieline?

- Important Dieline component

- Consider the Application

- Elements Required

- Nova Packaging – The Solution for You

- Wrap-Up

What is Dieline?

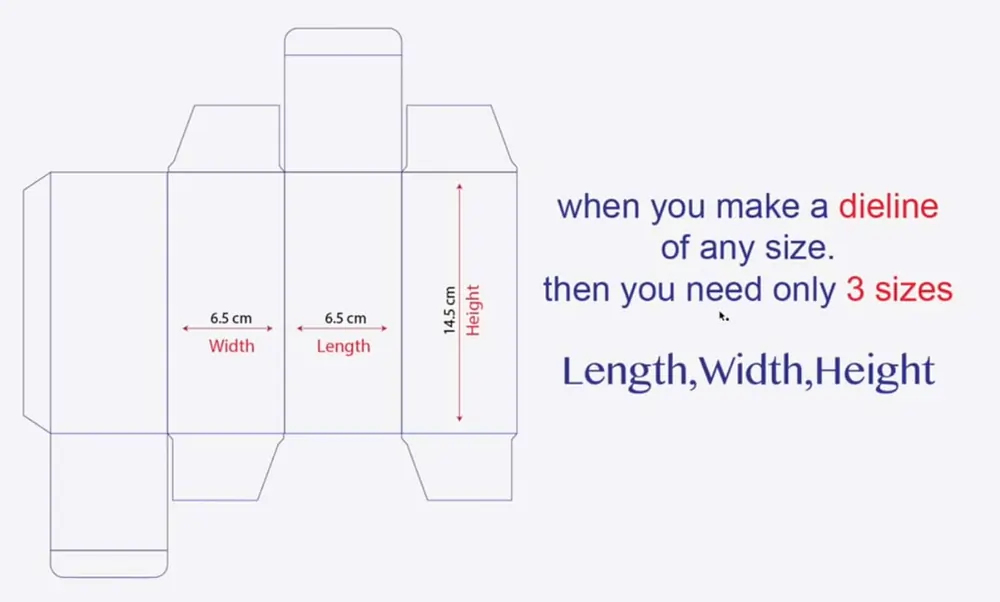

Have you ever heard of a dieline? It’s a technical term in packaging design that refers to a 2D template or blueprint. This template shows the exact layout and dimensions of the package design, including essential details such as folds, cuts, scores, and glue areas.

Designers and manufacturers use dielines to create physical packaging that matches the intended design. They are also helpful for identifying potential design flaws or issues before production begins, saving time and money in the long run.

You may also read The Importance of Custom Packaging Boxes for Businesses

What is a Dieline in Packaging?

A dieline is an essential tool used by packaging designers and manufacturers to create physical packaging that precisely matches the intended design. It’s essentially a 2D template or blueprint that provides the exact layout and dimensions of the package design, including details such as folds, cuts, scores, and glue areas.

By using dielines, designers can identify potential flaws or issues before production begins, saving both time and money.

What is a Dieline in Printing?

A dieline in printing is similar to its use in packaging. It’s still a 2D template or blueprint that outlines the key elements of the design, allowing print technicians to set up their machines more quickly and accurately. It also helps them identify any potential problems with alignment, color accuracy, etc., before printing begins.

You may also read How to Design Custom Packaging Boxes for Your Products

What is a Dieline Template?

A dieline template is simply a pre-made file containing all the necessary information for producing an accurate physical product from a given design. These templates usually come in vector format (.ai), so they can be easily edited in programs such as Adobe Illustrator or CorelDraw for further customization.

What is a Dieline in Illustrator?

In Adobe Illustrator (AI), a dieline is like any other vector graphic you might create in AI. It contains unique shapes and lines to create foldable packages or other products with multiple parts that must fit together correctly once assembled (like boxes).

These shapes provide precise measurements and guides so you know exactly how everything should come together without any guesswork.

What is a Label Dieline?

Label dielines are small-sized versions of regular dielines designed for creating labels instead of full-sized packages or products.

They typically contain less detailed information since label designs are more straightforward than larger projects. However, they still include all the necessary measurements and specifications to ensure accuracy when printed or cut out manually.

What is the Purpose of A Dieline?

The primary purpose of an accurate dieline is to ensure consistency between digital designs and their physical counterparts during manufacturing by providing precise measurements and indications as to where certain parts should be folded, scored, glued, etc., during assembly.

It allows designers to produce high-quality reproductions of their digital designs without worrying about whether they will match up correctly when they move into production stages later on down the line.

How to Create a Dieline?

Creating an accurate dieline requires knowledge of vector graphics software such as Adobe Illustrator (AI) or CorelDraw (CDR). Most vectors include basic shapes like rectangles, circles, and squares, which can be combined with special tools designed for creating foldable packages, such as “score & fold tools” found within AI/CDR software programs.

With these tools, you can easily measure distances between each part of your package design while adding creases & perforations, so everything comes together perfectly when it moves into production stages later!

How Do You Use a Dieline?

- Understand Your Package Design

Before using a dieline, you must clearly understand the package design you are creating. Ensure you have your design elements, measurements, and specifications ready to generate the dieline accurately.

- Create the Template

Using a vector-based graphics program like Adobe Illustrator or Inkscape, create a 2D template by setting up guidelines and other elements such as folds, cuts, scores, glue areas, etc. The more detailed your template is, the better your packaging will be in the end.

- Check for Errors

After creating the dieline, checking for errors or any potential issues before production begins is essential. Look for misspelled words or incorrect measurements and ensure everything looks good before progressing with production.

- Print Out Copies

Once you’re satisfied with your dieline, it’s time to print out copies of it for use in production. It’s best to print out multiple copies to ensure everyone involved in production has their copy of the dieline.

- Use the Dielines During Production

During the production process, use your dielines as a reference guide and refer back to them whenever necessary. It will help ensure that every step of production is done correctly and according to your original design plans.

Important Dieline component

The various components of a dieline can vary depending on the product, industry, and marketing decisions. These elements guide the manufacturer on where to cut and fold. Some critical components of a dieline are

- Trim line: This creates the final size of the product and defines its basic shape.

- Bleed line: Positioned outside the trim line creates a safe zone for the design elements and ensures sufficient placement space.

- Fold line: This indicates the position of the flaps and folds, whether on the top, sides, bottom, or in modified interiors.

- Perf line: These lines show where the product can be torn or cut off for specific marketing or design needs.

- Interior lines: Some products require internal markings for openings, handles, holes, or windows.

- Glue lines show where elements or folds should be glued together to create a stable shape.

Consider the Application

When creating a dieline, it’s essential to consider the intended use and application of the product. For example, if it’s a shipping container, it needs to be durable and easy to handle and store.

The visual appearance and brand storytelling are more important if it’s unique packaging for a new product line. And if it’s a three-dimensional marketing product like a retail display, both structural stability and appearance are crucial.

Your product’s application will help determine the container’s size, weight requirements, necessary flaps, holes, cuts, windows, where to place visual elements, and the best materials.

Research what other businesses in your industry are doing and consider your target market’s expectations. You can also use an existing product as a reference for your manufacturer or designer to create a similar dieline for your business.

Elements Required

- Dieline must have a bleed

It means that the printed image or design must extend to the edge of the dieline. It is necessary to avoid white edges when the product is cut out.

- Dieline must have a margin

It is the area between the printed image or design and the edge of the dieline. This margin is necessary to allow for slight variations in cutting and provide a place for any glue or adhesive that may be used.

- Dieline must have folded

Folds are necessary to create a three-dimensional product. Without folds, the product would be two-dimensional and unable to stand independently.

- Dieline must have cutouts

Cutouts are necessary to create openings in the product, such as for a handle or a spout. Cutouts also help to give the product a more three-dimensional look and feel.

- Dieline must have perforations

Perforations are small holes punched into the dieline. Perforations are necessary to allow the product to be opened or closed quickly, as well as to allow for ventilation if needed.

Nova Packaging – The Solution for You

If you are looking to create custom packaging for your business, it is essential to have a dieline that accurately represents your design. Creating a dieline can be a complex process, and mistakes can be costly. That’s why it’s important to work with an experienced packaging provider like Nova Packaging.

With years of industry expertise, their team can help you create the perfect dieline for your product, ensuring that your packaging looks great and performs well.

Contact Nova Custom Boxes today to get started on your custom packaging project.

Wrap-Up

To sum up, what is a dieline? It is a vital tool for creating custom packaging as it provides a detailed plan for the manufacturer to follow when cutting, folding, and gluing the final product. It includes essential components such as the trim line, bleed line, fold line, perf line, interior lines, and glue lines, which can be tailored to the packaging’s specific application and intended use.

By considering these elements and considerations when designing a dieline, businesses can produce packaging that looks great and serves its intended purpose effectively, ultimately boosting the brand image and product presentation.